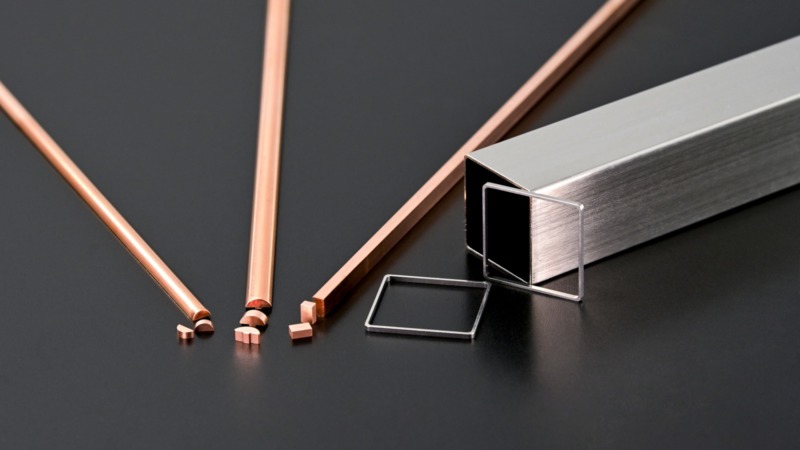

Clad Metal Pipe, Tube and Bar

Clad material (clad metal) is made by joining dissimilar metals. By combining metals of different properties it acquires unique characteristics that cannot be maintained with one material. By this way, we can enhance functional properties of product components such as weight reduction, corrosion resistance, and control thermal expansion coefficient.

We has long been working on manufacturing metal clad pipes and clad hollow bars with high dimensional accuracy by cold drawing, and is characterized by the technology that joins materials very strong such as diffusion bonding. In addition, various cross-section shapes can be produced, from round-bar shapes to pipes and irregular-shape materials, and the ratio of cross-sectional area can be changed freely using our own method so as to meet all requirements and challenges of its customers.

Some tips for useful combination of functional characteristics of clad materials

● Conductivity x Lightweightness

● Strength x Conductivity

● Corrosion Resistance x Lightweightness

● Thermal Conductivity x Strength

● Magnetic Property x Conductivity

● X-ray Opacity x Conductivity

● Biocompatibility x Strength

Types and applications of clad rods and wires

| Usage | Material | Properties | |

|---|---|---|---|

| Outer | Core material | ||

| Plating electrode | Titanium | Copper and Aluminum |

Corrosion resistance x Electrical conductivity |

| Electrode for refining |

Stainless Steel and Titanium |

Copper and Aluminum |

Corrosion resistance x Electrical conductivity |

| Dumet Wire | Copper | Ni Alloy |

Conductivity x Strength |

| Lightning Rod | Copper | Carbon Steel |

Conductivity x Strength |

| Voice coil | Copper | Aluminum |

Conductive x Lightweight |

| Washer | Carbon Steel | Aluminum |

Strength, weldability x light weight |

Types and applications of clad tubing

| Equipment | Material | Fluid | ||

|---|---|---|---|---|

| Outer tube | inner tube | Outer | inner | |

| Ammonia Condenser | Low carbon steel | Copper and copper alloys | Ammonia | Water |

| Oil refinery | Low Carbon Steel | Copper | Oil | Water |

| Coke Cooler | Low Carbon Steel | Copper and Copper Alloys | Naphthalene, etc. | Water |

| Pump piping | Low carbon steel | Copper alloy | Air or Soil | Water |

| Ammonia Condenser Chillers | Copper and copper alloys | Low carbon steel | Water | Ammonia |

| Scientific Condensers | Stainless Steel | Cupronickel | Chemicals | Water |

| Beverage, cosmetics, medicine, food, plastic industry, etc. |

Aluminum or Stainless Steel |

Copper or copper alloy | Raw materials | Water |

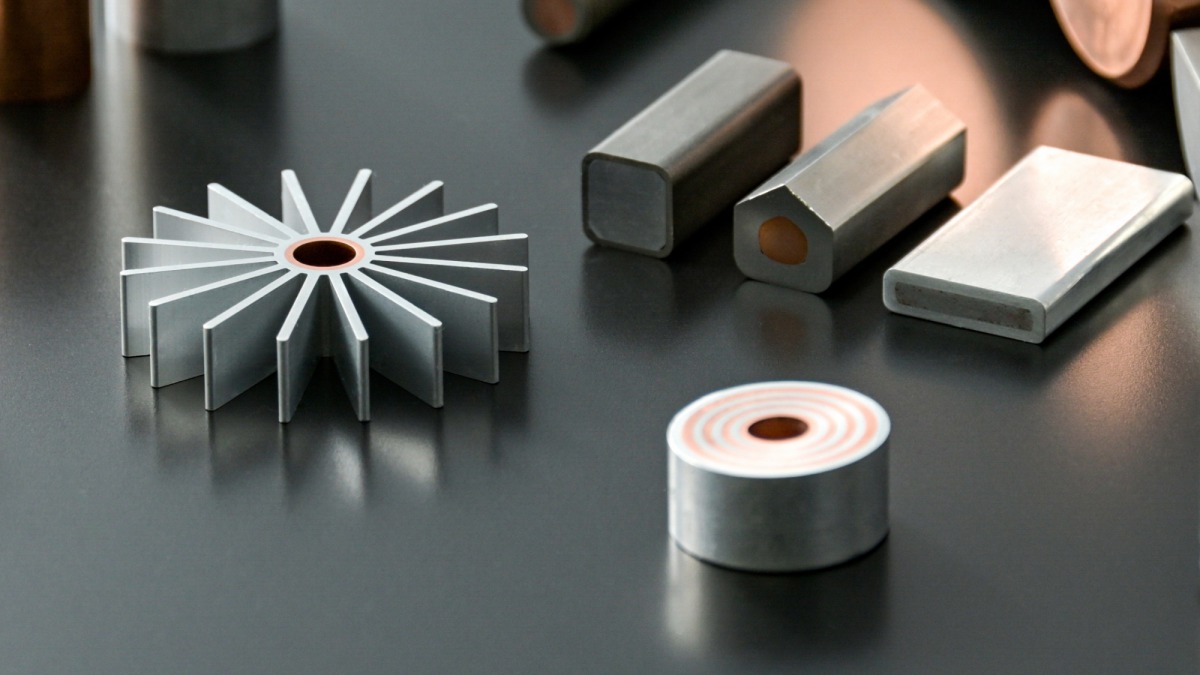

Various shaped clad tube and bar / Metal composite material

Development of new components and functional materials with multi-layer clad pipes

Multi-layer clad hollow bar materials are constructed with two or more layers, adding more complex functions. Utilizing various processing technologies such as joint adjustment of specially shaped multi-layer clad pipes, heat treatment, cutting, and bending, we handle everything from manufacturing to analytical tests that requires high level of in-house technology. We promptly respond to our customers’ requests, from material development, product design of new materials, to solving problems of existing materials.

Materials Processing

- Cold drawn

- Swaging process

- Metal straightening

- Correction

- Cutting process

- Heat treatment

- Solvent degreasing process

- Polishing

Functional

- Thinning

- High dimensional accuracy

- Quality stable

- Thermal conductivity

Industrial fields

- Medical equipment

- Electrode