Ultra-precision cutting parts and precision metalworking

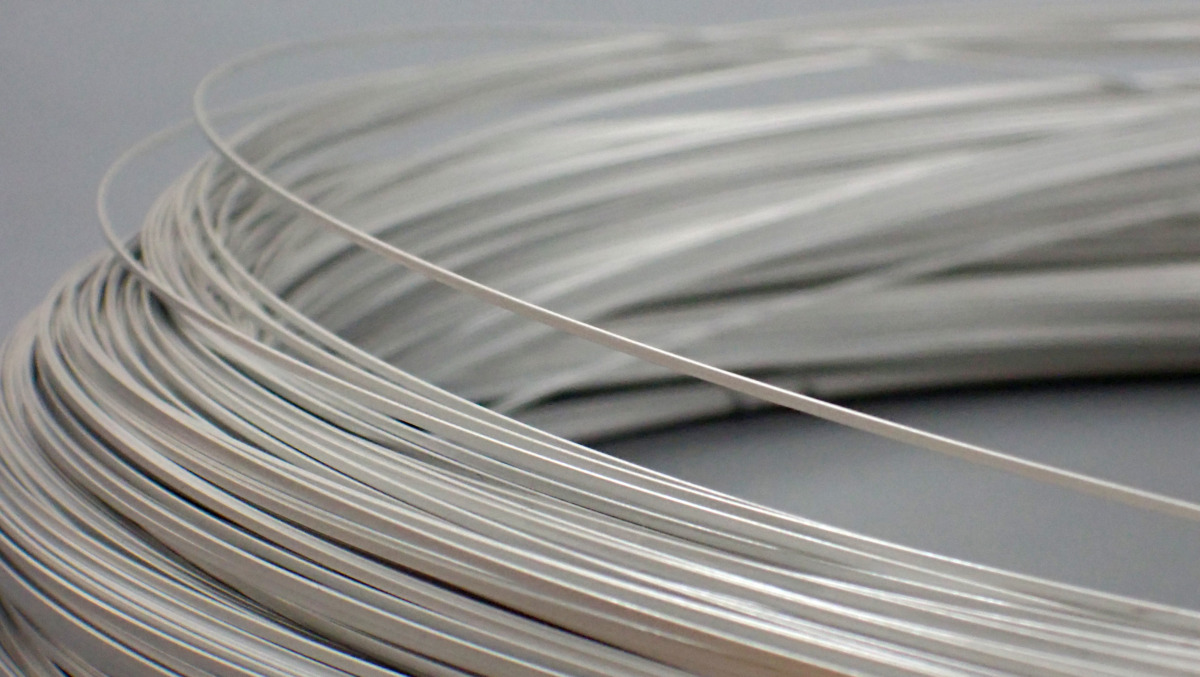

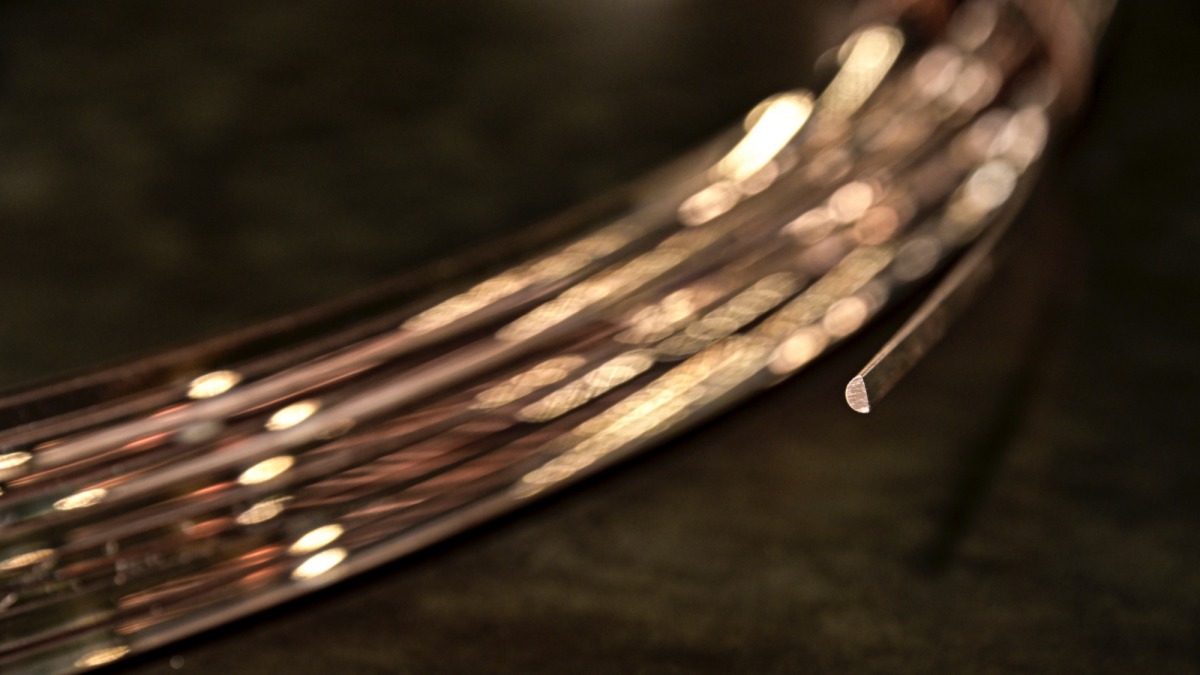

In metal processing of precision parts and manufacturing of precision machine parts and precision small parts, our proprietary technologies developed over many years enable precision slitting and slicing of wire and bar and pipe materials down to 0.5 mm or less with high accuracy and precision cutting.

We manufacture custom heat sinks, semiconductor materials, and electronic components.

Precision cutting and slitting of heat sinks, copper, molybdenum and aluminum heat sinks, and heat dissipating base components

We manufacture slit fabricated products related to electronic components, such as small heat sinks for substrate loading that support fine fin structures. Slit processing with a pitch width of 0.5 mm or less and height of 5 mm or more is available for manufacturing upon request. Compared to scribing, extrusion, cold forging, etching, and cutting, Kansai Pipe Industry's proprietary cutting technology for manufacturing heat sinks offers a higher degree of freedom in tongue ratio and enables batch cutting by specifying precise fin pitch and fin height, and is effective in boiling cooling heat exchangers and other applications. We manufacture high-density and high-precision precision cut parts that can be applied to all kinds of heat exchanger parts, including semiconductor-related parts, automotive parts, and precision heat sinks for industrial equipment.

Micro high-precision cutting and slicing

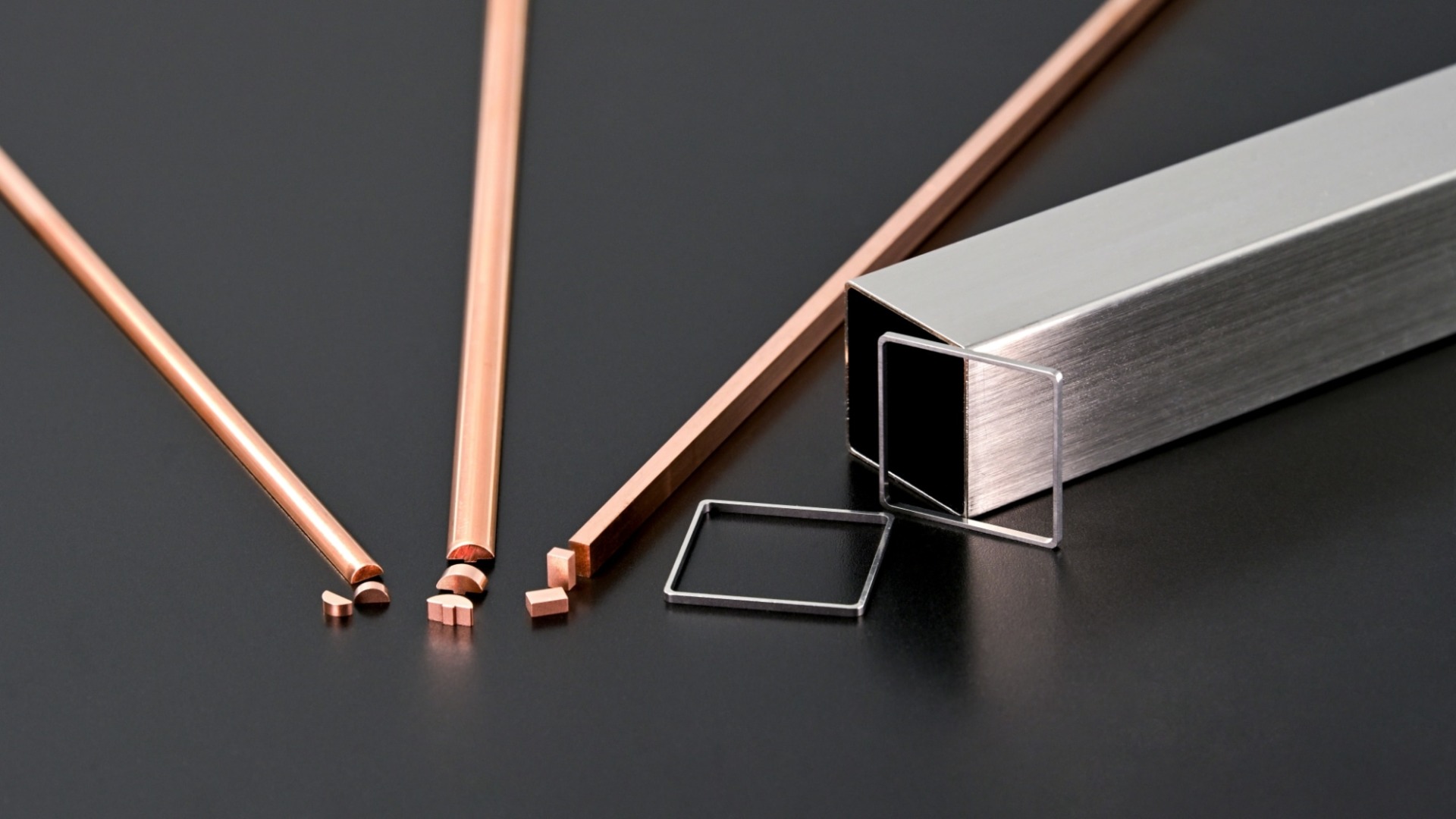

Manufacture of electronic parts and precision industrial parts by ultra-precision cutting, such as Aluminum oxide dispersion strengthened copper (ODS) deformed bars and Kovar pipes

We manufacture electronic components such as deformed rods of Aluminum oxide dispersion strengthened copper (ODS) and square pipes of Kovar, which are ultra-precision cut to any desired length. Our proprietary cutting technology eliminates burrs and deformation, making it suitable for mass production of high-quality electronic components.

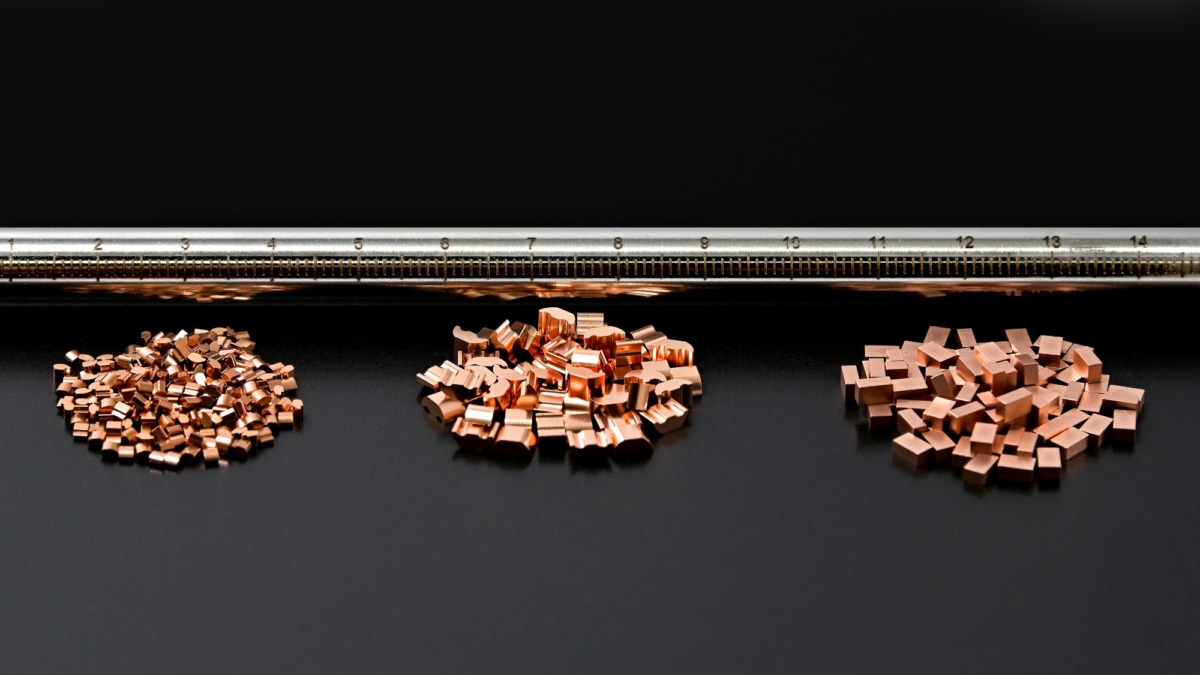

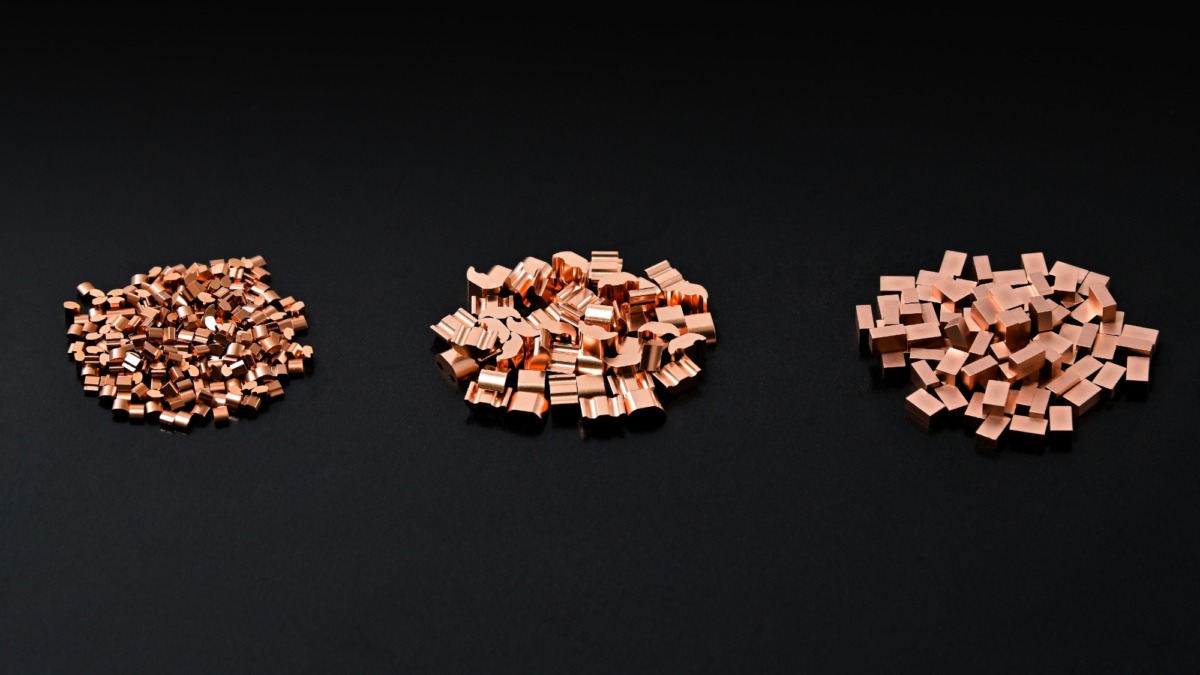

Mass production of deformed heat sinks by batch cutting of deformed wires and rods of various shapes

Based on the high-precision manufacturing technology for deformed wires, rods and various metal pipe parts that we have cultivated over the years, we mass-produce precision electronic parts such as deformed heat sinks by slice cutting using our precision cutting technology.

By providing one-stop services from precision cutting and welding to analysis and inspection, we have solved many problems such as improving efficiency and high precision during mass production.In addition to electronic components and heat exchangers, also applies to precision industrial components in various fields.

Equipments

| Equipment name | Specifications | Uses and Features | Number of machines |

|---|---|---|---|

| Multiwire saw | 150㎜ × 150㎜ × 300㎜ Cutting pitch 0.5㎜ to 5㎜ | Mass production facilities for short products and ultra-precision cutting | 2 |

Materials Processing

- Cold drawn

- Cutting process

- Solvent degreasing process

- Precision machining

- Long materials

Functional

- Thermal conductivity

- Space saving

- Manufacturing cost reduction

- thinning out

- heat dissipation property

- Weight saving

- Mass production

- High dimensional accuracy

- superconductivity

- Electrical conductivity

- Long life

- Design

Industrial fields

- Environmental energy

- OEM and ODM

- Electronic Materials

- ICT

- Air conditioner

- Automotive parts

- Semiconductors

- Medical equipment